Project Assistant Professor, GSID, Nagoya University

Alla OLIFIRENKO

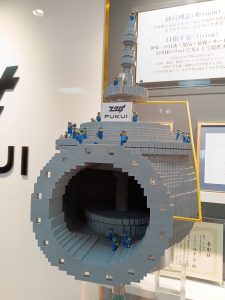

On February 16, 2024, I had the opportunity to accompany Prof. Keiko ZAIMA and Prof. Hiroshi MACHIDA, the leaders of Research Groups 4 (Climate Change and Corporate Management) and 5 (Climate Change Related Technologies and CC(U)S)), respectively, to a symposium hosted by Fukui Seisakusho, Co., Ltd — a manufacturer of safety valves located in Hirakata, Osaka, Japan.

This compact but extremely informative event, titled “Huge possibility but small scale in Hirakata”, included a guided tour of the company’s manufacturing facilities, as well as presentations of the host company, the experts of the Research Institute of Innovative Technology for the Earth (RITE), Mr. Yutaka TANAKA, an independent consultant in the fields of resources, energy and CCS, and the members of H2Governance project.

At the heart of the discussion was the process of carbon dioxide capture, (utilisation), and storage (CC(U)S), a technology that is rapidly growing in popularity as one of the means to balance greenhouse gas emissions, especially in hard-to-abate sectors such as power generation, chemical, steel or cement manufacturing.

CCS/CCU involves capturing carbon dioxide from emission sources such as power plants or industrial facilities and transporting it for use or storage on the continent or in the ocean through pipelines, ships, or trucks. With this technology, carbon dioxide is either no longer emitted into the atmosphere or can be used and reused in a variety of ways, such as a raw material for industrial products. Most people are familiar with at least one of the uses – dry ice, the solid state of CO2.

Many countries around the world, such as the United States, Australia, China, Norway, and the UK, have CCS projects that are either already operational or in construction and are adopting specialized legislation for their commercialization. In Japan, as in most countries, there is a legislative gap in this regard, and projects are still in development, albeit having access to competitive technologies such as synthetic fuel production with CO2. My home country, Ukraine, has only recently started to look into CCS as a possible component of its decarbonization efforts, as highlighted in its COP28 report.

Given my specialization, I am accustomed to focusing primarily on the legal environment to make the transition to clean energy as smooth as possible for businesses. However, the main takeaway from the event was rather unexpected.

A visit to a manufacturer of safety valves used in the energy supply chain made me realize that no matter how easy the certification may be or how strict the legal standards are, it will all be in vain if the carrier tanks risk exploding due to the use of parts unsuitable for new processes.

Safety valves are devices that are installed on systems for storing and transporting liquids or gases to prevent mechanical damage to equipment due to excessive pressure. As substances expand when transitioning from a liquid to a gaseous state, they increase pressure inside the container. The safety valve releases the excess substance and closes once the optimal pressure is restored.

Such valves are widely used in industrial environments but are particularly crucial for handling energy sources, which often involves extreme temperatures and pressure. However, it is only one of countless elements of the global supply and value chains on which decarbonization fully depends.

With this realization, I concluded that there can be no single key to achieving carbon neutrality. Addressing such a complex problem requires harmonious and conscious cooperation of every large, medium, and small player in the market. Each company and each manager should become environmentally aware and willing to cooperate.

As for Fukui Seisakusho, there is no doubt that this company has both the environmental awareness and technical capability to contribute to achieving net zero. Although the company currently holds the world’s largest share in the Liquified Natural Gas (LNG) carrier market, by 2036 it aims to become a leader in producing safety valves for the energy sector in a carbon-neutral society, which includes methanation, biomass, ammonia fuel, and, of course, CCUS and hydrogen (the initiative they call FUKUI VISION 2036). I was amazed at how young were the employees of the company, and how eager they seemed to move forward despite having to pioneer their way in this rather new area. This is reassuring.

I hope that even in the absence or lack of appropriate governance, more and more companies realize the need to study and adopt practices that meet the demands of our time—a time when energy security and fighting climate change are not just an economic necessity but also a matter of human survival, and take initiative in transforming their business practices without waiting for top-down regulation.